SMT PCB assembly has become the backbone of modern electronics production, enabling faster, lighter, smaller, and more reliable devices across every industry. As products continue to shrink while requiring higher performance, surface-mount technology offers the precision, flexibility, and efficiency needed to meet today’s technological demands. From smartphones and medical instruments to automotive systems and advanced industrial equipment, SMT PCB assembly plays a key role in ensuring that electronic products achieve the functionality and reliability expected in today’s competitive market.

Contents

- 1 Understanding SMT PCB Assembly

- 2 How SMT Differs From Traditional Methods

- 3 The SMT PCB Assembly Process

- 4 Reflow Soldering and Inspection

- 5 Why SMT PCB Assembly Is Used Across Every Industry

- 6 Supporting Miniaturization and Innovation

- 7 The Benefits of Professional SMT PCB Assembly

- 8 Cost Efficiency and Faster Production

- 9 Reliability and Performance in Every Application

- 10 Ensuring Compliance With Industry Standards

Understanding SMT PCB Assembly

Surface-mount technology, commonly known as SMT, involves mounting electronic components directly onto the surface of a printed circuit board without the need for drilled holes. This method revolutionized electronic manufacturing by allowing components to be placed closer together, increasing circuit density and enabling more powerful systems on compact boards. SMT PCB assembly reduces the size, weight, and cost of electronic devices, making it essential in both consumer electronics and high-performance industrial applications.

How SMT Differs From Traditional Methods

SMT PCB assembly differs from through-hole assembly in several important ways. Instead of inserting leads into drilled holes, SMT components are placed on pads with solder paste, then soldered using reflow technology. This allows for automation at every stage, resulting in unmatched precision and consistency. SMT is ideal for mass production because machines can place thousands of components per hour with minimal error. The ability to mount components on both sides of a PCB also increases design flexibility and supports more complex circuitry.

The SMT PCB Assembly Process

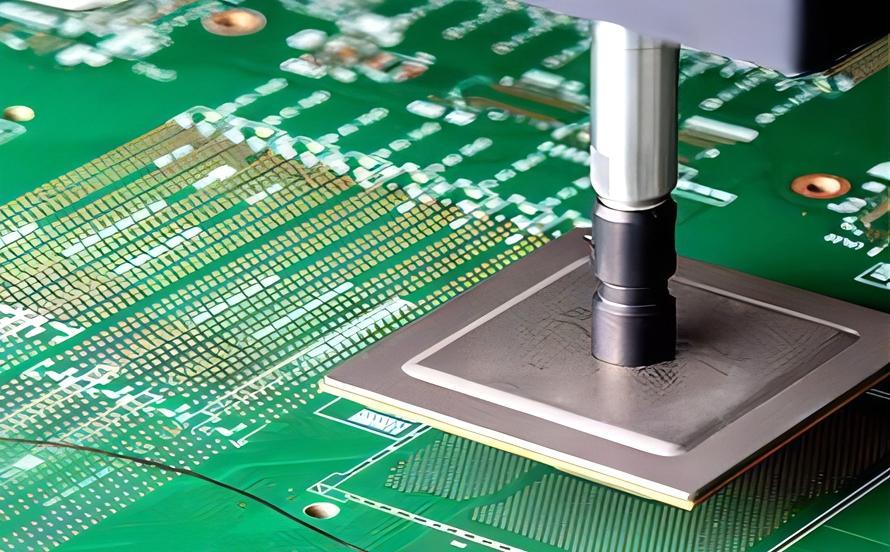

The SMT PCB assembly process includes several detailed steps designed to achieve accuracy and flawless functionality. It begins with PCB preparation and solder paste application using a fine stainless-steel stencil. This ensures that each pad receives the right amount of solder paste. Next, automated pick-and-place machines position components on the board with remarkable precision, guided by CAD data and advanced vision systems.

Reflow Soldering and Inspection

Reflow soldering is the critical step where the board is heated in a controlled environment, causing the solder paste to melt and form strong electrical and mechanical connections. After reflow, every PCB undergoes AOI inspection to detect issues such as solder bridges, misalignment, or missing parts. For complex boards, X-ray inspection is used to evaluate hidden joints—especially BGAs and fine-pitch components. These quality checks ensure that every SMT PCB assembly meets industry standards and performs reliably under real-world conditions.

Why SMT PCB Assembly Is Used Across Every Industry

SMT PCB assembly is widely adopted because it addresses the growing need for compact, high-performance electronics. Industries such as telecommunications, medical equipment, aerospace, consumer electronics, industrial automation, and automotive electronics rely heavily on SMT for its speed, consistency, and efficiency. With SMT, manufacturers can build devices with sophisticated functionalities while maintaining lightweight and sleek designs.

Supporting Miniaturization and Innovation

Electronics continue to evolve, requiring smaller components that deliver greater performance. SMT enables manufacturers to accommodate micro-sized components such as 01005 resistors, fine-pitch ICs, microcontrollers, and BGA packages. This supports advanced technologies like IoT devices, wearable electronics, smart sensors, and high-speed communication modules. By offering higher component density, SMT PCB assembly allows engineers to design more intelligent and more efficient devices without increasing PCB size.

The Benefits of Professional SMT PCB Assembly

Working with experienced SMT PCB assembly specialists ensures a level of quality that is difficult to achieve with small internal setups. Professional facilities use advanced pick-and-place equipment, high-speed reflow ovens, automated inspection systems, and controlled material handling practices. This combination of technology and expertise results in dependable solder joints, low defect rates, and consistent production across large volumes.

Cost Efficiency and Faster Production

SMT PCB assembly is not only more precise but also more economical. Automated processes reduce labor costs, minimize human error, and enable rapid production cycles. Manufacturers benefit from shorter lead times and stable output quality, which is essential for businesses aiming to scale quickly or enter competitive markets. When properly implemented, SMT offers long-term cost savings through improved product reliability and reduced rework or warranty issues.

Reliability and Performance in Every Application

SMT PCB assembly enhances long-term durability by improving electrical performance and reducing mechanical stress. Because components sit directly on the PCB surface, the connections are more stable and less prone to mechanical failure compared to through-hole parts in high-vibration environments. This makes SMT ideal for automotive electronics, industrial machinery, aerospace devices, and medical equipment where performance cannot be compromised.

Ensuring Compliance With Industry Standards

Professionally managed SMT PCB assembly ensures compliance with RoHS, IPC standards, and customer-specific requirements. Specialized technicians, rigorous testing, and documented processes help guarantee that each finished PCB supports the intended application safely and reliably. High-quality assembly is vital for industries where even minor defects can lead to significant operational or safety risks.

Choose Expert PCB Assembly Services for High-Quality SMT Production

For businesses looking to improve product performance with high-precision SMT PCB assembly, partnering with experienced PCB assembly services providers ensures superior quality, faster turnaround, and scalable production. With advanced equipment, expert engineering, and strong quality control systems, the right assembly partner can help you bring your electronic designs to life with reliability and efficiency.